Links:

-

In addition to their practical benefits, snake spacers can also add a decorative touch to a snake enclosure. They come in a variety of colors and designs, allowing snake keepers to personalize their pet's habitat and create a visually appealing environment for their snake. Another common use for mini wire grid panels is in trade show booths and craft fairs. These panels can be quickly assembled and disassembled, making them ideal for temporary displays

mini wire grid panels. Artists and vendors can attach shelves and hooks to showcase their products, creating an eye-catching display that attracts customers and maximizes sales potential. When choosing concrete reinforcing mesh for sale, it is important to consider the size, shape, and configuration that best suits the requirements of the project. The mesh should be properly installed and secured to ensure that it effectively reinforces the concrete structure. It is also important to consult with a structural engineer or construction professional to determine the appropriate type and quantity of reinforcing mesh needed for the project. The size and strength of the wire tie are determined by the specific requirements of the project Floral wire is an essential tool for anyone who loves working with flowers and creating beautiful arrangements. The versatile wire can be used in a variety of ways to enhance and support floral designs. From securing stems in place to creating intricate shapes and designs, floral wire is a must-have for any florist or DIY enthusiast. Firstly, let's talk about the benefits of buying chicken wire in bulk. The most obvious advantage is cost savings. When you buy chicken wire in bulk, you can get a lower price per roll compared to purchasing it individually. This means that you can save money while still getting the quality and durability you need for your projects. In the realm of gardening and horticulture, plant stakes play a crucial role that often goes unnoticed. They are more than just garden accessories; they are supportive tools that ensure the robust growth and healthy development of plants. This article delves into the significance of plant stakes and their multifaceted benefits. Galvanised steel mesh is also a popular choice for decorative and architectural purposes. The sleek and modern appearance of the material makes it a stylish option for use in interior and exterior design projects. Whether used for railing infill panels, decorative screens, or art installations, galvanised steel mesh can add a touch of contemporary elegance to any space.

Horizontal joint reinforcement is an integral component in masonry construction, crucial for enhancing the structural stability of walls. This reinforcement consists of steel wire placed within the mortar joints between masonry units. Its primary function is to control and mitigate the effects of cracking due to thermal expansion, contraction, and structural loads. By providing additional tensile strength, horizontal joint reinforcement helps in distributing loads more evenly across the wall, thus preventing localized stress concentrations that could lead to structural failures. This method is particularly beneficial in areas prone to seismic activity, where buildings must withstand lateral forces without compromising their structural integrity.

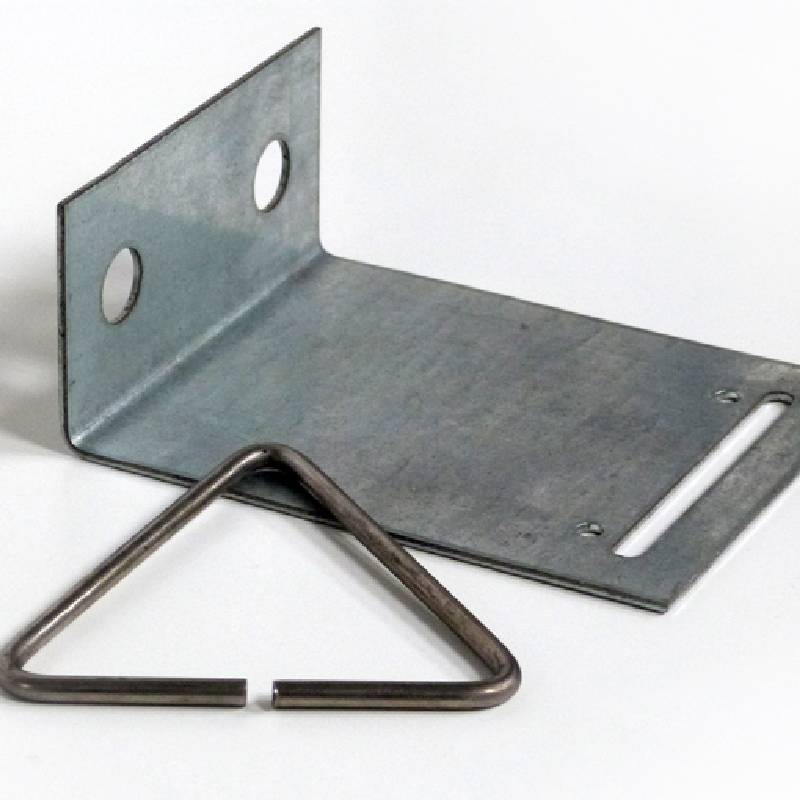

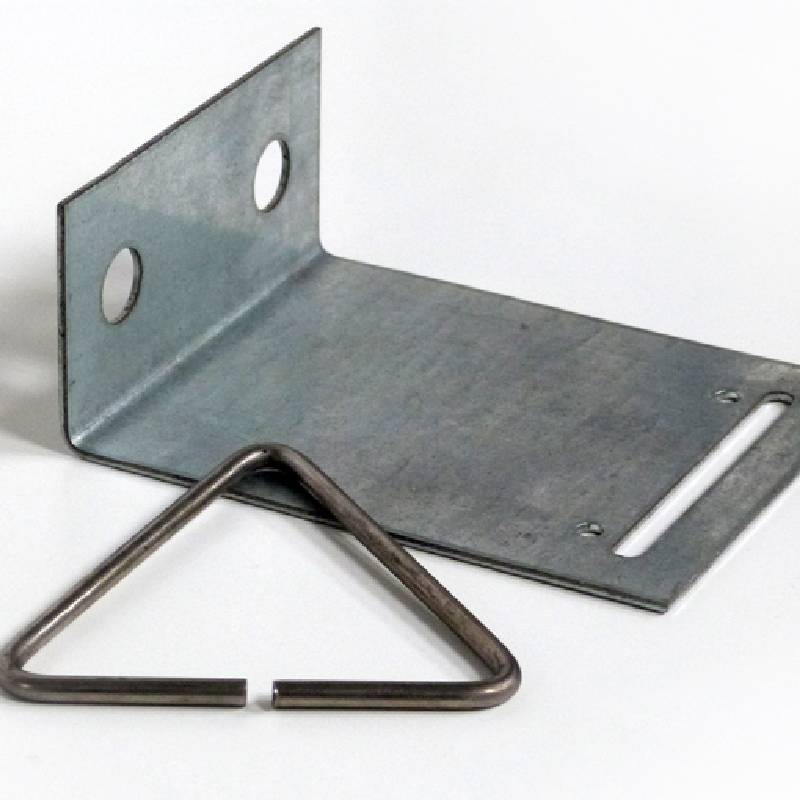

3. Production Process Advanced technology and equipment can lead to higher prices. Another benefit of galvanised steel mesh sheets is their versatility. They come in a variety of sizes and thicknesses, making them suitable for a wide range of projects. Whether you need a small piece of mesh for a DIY project or a large sheet for a commercial application, you can easily find a size that suits your needs. Additionally, galvanised steel mesh sheets can be easily cut, bent, and shaped to fit specific requirements, making them a flexible choice for a variety of applications. 1. Material selection The first step is to select the appropriate material based on the specific requirements of the application. There are several different types of cavity ties available, each designed for specific applications and construction requirements. These include wall starters, channel ties, and twist ties, among others. The choice of cavity tie will depend on factors such as the type of wall construction, the materials being used, and the environmental conditions of the site. In industrial settings, diamond wire mesh is employed in mining and quarrying operations for sieving and screening purposes. Its durable nature withstands the harsh conditions and abrasive materials, ensuring efficient separation and processing. Overall, DW-10HS veneer anchors are a reliable and efficient anchoring solution for securing veneer panels to structural walls. Their versatility, durability, and high load-bearing capacity make them an ideal choice for a wide range of veneer projects. By choosing DW-10HS anchors, builders and contractors can ensure the stability, safety, and longevity of their veneer installations. When working with thick metal wire, it's important to remember that it can be difficult to work with due to its stiffness. However, there are several techniques you can use to manipulate the wire and achieve the desired shape. For example, you can use pliers to bend and shape the wire, or you can use a torch to heat the wire and make it more malleable. With a little practice, you'll be able to create beautiful and intricate designs with thick metal wire. When considering the cost per foot of cattle fence, it's also essential to factor in the terrain and climate of your region. For example, in areas prone to heavy snowfall, a sturdier fence that can withstand the weight of snow might be necessary, potentially increasing costs. Conversely, in arid regions, materials that resist corrosion and do not require as much maintenance could save money in the long term. One of the key benefits of using a 12% tomato cage is that it allows for proper air circulation around the plant. This is essential for preventing diseases such as blight, which can quickly spread in a moist and crowded environment. The open design of the cage allows air to flow freely around the plant, reducing the risk of disease and promoting healthy growth. Secondly, wire clips facilitate faster and more efficient construction. Their simple installation process minimizes the need for additional materials and labor-intensive techniques, saving time and resources. With the right tools, they can be quickly attached to the steel framework, allowing the bricks to be laid in a seamless sequence With the right tools, they can be quickly attached to the steel framework, allowing the bricks to be laid in a seamless sequence With the right tools, they can be quickly attached to the steel framework, allowing the bricks to be laid in a seamless sequence With the right tools, they can be quickly attached to the steel framework, allowing the bricks to be laid in a seamless sequence

With the right tools, they can be quickly attached to the steel framework, allowing the bricks to be laid in a seamless sequence With the right tools, they can be quickly attached to the steel framework, allowing the bricks to be laid in a seamless sequence wire clips for brick wall. Gardening is an enjoyable and rewarding activity that allows individuals to connect with nature, grow their own food, and enhance the aesthetic appeal of their outdoor spaces. However, achieving optimal gardening results requires the use of high-quality tools and materials. One such essential item is garden wire, which is used for various purposes such as supporting plants, creating boundaries, and managing pests. In this article, we will discuss the benefits of using 1.6mm garden wire for effective gardening. In conclusion, a brick tie is a small yet significant component in cavity wall construction. It serves as a silent hero, working behind the scenes to bind two separate walls together while providing numerous benefits such as improved energy efficiency, enhanced structural stability, and increased longevity of the building. The next time you admire a well-built brick facade, remember the humble brick tie playing its part in ensuring your safety and comfort within those sturdy walls. 4. Ease of Installation Installing 1.6mm garden wire is a straightforward process that can be completed quickly and easily. All you need is a pair of wire cutters and some basic gardening tools, and you can have your garden wire installed in no time. This makes it an ideal choice for those who want to get started with gardening but may not have a lot of experience or tools. The Artistic Elegance of Wire Grid Panels Display Joint reinforcement primarily serves two purposes. Firstly, it increases the tensile strength of the masonry, which is inherently weak in tension. By providing a continuous load path through the joints, it helps resist forces that tend to pull the masonry apart. Secondly, it improves the shear resistance of the structure, enhancing its ability to withstand lateral loads such as wind or earthquake forces. The term metal rib lath refers to a type of metal mesh that is specifically designed with parallel ribs or ridges running across its surface. These ribs serve as anchor points for the plaster or stucco, providing a strong bond and ensuring even coverage. Made primarily from galvanized steel or aluminum, this lathing system is highly resistant to corrosion, making it suitable for both interior and exterior applications. 1. In your Spring controller or service class, call the `compressVideo` and `decompressVideo` methods from the `VideoCompressionService` class to handle video compression and decompression respectively. One of the key attractions of rose gold craft wire lies in its aesthetic appeal. Its rosy-pink hue exudes a subtle, yet striking charm, adding a touch of luxury to any creation. It pairs beautifully with a range of colors, from pastels to deep jewel tones, making it ideal for designing jewelry, home decor, and even floral arrangements. One of the key benefits of using a tomato plant support cage is that it helps to improve air circulation around the plant. This can prevent diseases such as blight and powdery mildew, which thrive in humid conditions with poor air circulation This can prevent diseases such as blight and powdery mildew, which thrive in humid conditions with poor air circulation

wire clips for brick wall. Gardening is an enjoyable and rewarding activity that allows individuals to connect with nature, grow their own food, and enhance the aesthetic appeal of their outdoor spaces. However, achieving optimal gardening results requires the use of high-quality tools and materials. One such essential item is garden wire, which is used for various purposes such as supporting plants, creating boundaries, and managing pests. In this article, we will discuss the benefits of using 1.6mm garden wire for effective gardening. In conclusion, a brick tie is a small yet significant component in cavity wall construction. It serves as a silent hero, working behind the scenes to bind two separate walls together while providing numerous benefits such as improved energy efficiency, enhanced structural stability, and increased longevity of the building. The next time you admire a well-built brick facade, remember the humble brick tie playing its part in ensuring your safety and comfort within those sturdy walls. 4. Ease of Installation Installing 1.6mm garden wire is a straightforward process that can be completed quickly and easily. All you need is a pair of wire cutters and some basic gardening tools, and you can have your garden wire installed in no time. This makes it an ideal choice for those who want to get started with gardening but may not have a lot of experience or tools. The Artistic Elegance of Wire Grid Panels Display Joint reinforcement primarily serves two purposes. Firstly, it increases the tensile strength of the masonry, which is inherently weak in tension. By providing a continuous load path through the joints, it helps resist forces that tend to pull the masonry apart. Secondly, it improves the shear resistance of the structure, enhancing its ability to withstand lateral loads such as wind or earthquake forces. The term metal rib lath refers to a type of metal mesh that is specifically designed with parallel ribs or ridges running across its surface. These ribs serve as anchor points for the plaster or stucco, providing a strong bond and ensuring even coverage. Made primarily from galvanized steel or aluminum, this lathing system is highly resistant to corrosion, making it suitable for both interior and exterior applications. 1. In your Spring controller or service class, call the `compressVideo` and `decompressVideo` methods from the `VideoCompressionService` class to handle video compression and decompression respectively. One of the key attractions of rose gold craft wire lies in its aesthetic appeal. Its rosy-pink hue exudes a subtle, yet striking charm, adding a touch of luxury to any creation. It pairs beautifully with a range of colors, from pastels to deep jewel tones, making it ideal for designing jewelry, home decor, and even floral arrangements. One of the key benefits of using a tomato plant support cage is that it helps to improve air circulation around the plant. This can prevent diseases such as blight and powdery mildew, which thrive in humid conditions with poor air circulation This can prevent diseases such as blight and powdery mildew, which thrive in humid conditions with poor air circulation This can prevent diseases such as blight and powdery mildew, which thrive in humid conditions with poor air circulation This can prevent diseases such as blight and powdery mildew, which thrive in humid conditions with poor air circulation

This can prevent diseases such as blight and powdery mildew, which thrive in humid conditions with poor air circulation This can prevent diseases such as blight and powdery mildew, which thrive in humid conditions with poor air circulation tomato plant support cage. By keeping the plant off the ground and allowing air to flow freely around it, the cage helps to create a healthier growing environment for the tomato plant. In conclusion, diamond wire mesh, with its unique diamond pattern and exceptional strength, has become an indispensable material across multiple industries. Its ability to provide both practical solutions and aesthetic enhancements underscores its true value. As technology advances and design aesthetics evolve, the potential of diamond wire mesh seems limitless, promising a future of innovative applications and artistic expressions. In general, wall ties are designed to last for the lifetime of a building, which can range from 50 to over 100 years. However, there are several factors that can affect the longevity of wall ties. One of the main factors is the material of the ties. Stainless steel wall ties are commonly used in construction due to their durability and resistance to corrosion. These ties can last for decades without needing replacement, as long as they are installed correctly and not subjected to extreme conditions. Installation of a 47% 20-inch field fence requires careful planning and execution

tomato plant support cage. By keeping the plant off the ground and allowing air to flow freely around it, the cage helps to create a healthier growing environment for the tomato plant. In conclusion, diamond wire mesh, with its unique diamond pattern and exceptional strength, has become an indispensable material across multiple industries. Its ability to provide both practical solutions and aesthetic enhancements underscores its true value. As technology advances and design aesthetics evolve, the potential of diamond wire mesh seems limitless, promising a future of innovative applications and artistic expressions. In general, wall ties are designed to last for the lifetime of a building, which can range from 50 to over 100 years. However, there are several factors that can affect the longevity of wall ties. One of the main factors is the material of the ties. Stainless steel wall ties are commonly used in construction due to their durability and resistance to corrosion. These ties can last for decades without needing replacement, as long as they are installed correctly and not subjected to extreme conditions. Installation of a 47% 20-inch field fence requires careful planning and execution 47 inch field fence. The fence should be installed at an appropriate height, usually around 4 to 5 feet tall, depending on the size of the livestock. Posts should be placed at regular intervals to ensure stability, with corner posts and line posts strategically positioned for added strength. Proper grounding is essential too, especially if an electric fence system is used to enhance the barrier's effectiveness. Overall, black wire grid panels are an excellent choice for anyone looking to create a stylish and organized space. Their versatility, durability, and aesthetic appeal make them a popular option for a wide range of settings. Whether used in a retail store, home office, or craft room, these grids are sure to enhance the functionality and visual appeal of any space. In conclusion, rose gold craft wire is more than just a material; it's a canvas for creativity, a bridge between traditional craftsmanship and modern aesthetics. Its unique color and flexibility inspire artists to push boundaries, explore new designs, and create works of art that resonate with both elegance and personality. So, whether you're a seasoned crafter or just starting your creative journey, let the allure of rose gold craft wire guide you into a world of infinite possibilities. Iron wire, an essential material in various industries, plays a pivotal role in construction, manufacturing, agriculture, and more. Its wholesale availability ensures a consistent supply to meet the ever-increasing global demand. This article delves into the significance of wholesale iron wire, its applications, and its impact on the economy. Regardless of the chosen system, proper installation is critical. This includes ensuring adequate drainage behind the veneer, proper flashing to prevent water infiltration, and regular maintenance to check for any signs of damage or wear. Regular inspections can help identify potential issues early, preventing costly repairs down the line. Wholesale chicken wire fencing is a cost-effective and versatile solution for securing and containing poultry and other animals on a farm or in a backyard. This type of fencing is made from galvanized steel wire that is woven into a hexagonal mesh pattern, creating a strong and durable barrier that can withstand the elements and potential damage from animals.

47 inch field fence. The fence should be installed at an appropriate height, usually around 4 to 5 feet tall, depending on the size of the livestock. Posts should be placed at regular intervals to ensure stability, with corner posts and line posts strategically positioned for added strength. Proper grounding is essential too, especially if an electric fence system is used to enhance the barrier's effectiveness. Overall, black wire grid panels are an excellent choice for anyone looking to create a stylish and organized space. Their versatility, durability, and aesthetic appeal make them a popular option for a wide range of settings. Whether used in a retail store, home office, or craft room, these grids are sure to enhance the functionality and visual appeal of any space. In conclusion, rose gold craft wire is more than just a material; it's a canvas for creativity, a bridge between traditional craftsmanship and modern aesthetics. Its unique color and flexibility inspire artists to push boundaries, explore new designs, and create works of art that resonate with both elegance and personality. So, whether you're a seasoned crafter or just starting your creative journey, let the allure of rose gold craft wire guide you into a world of infinite possibilities. Iron wire, an essential material in various industries, plays a pivotal role in construction, manufacturing, agriculture, and more. Its wholesale availability ensures a consistent supply to meet the ever-increasing global demand. This article delves into the significance of wholesale iron wire, its applications, and its impact on the economy. Regardless of the chosen system, proper installation is critical. This includes ensuring adequate drainage behind the veneer, proper flashing to prevent water infiltration, and regular maintenance to check for any signs of damage or wear. Regular inspections can help identify potential issues early, preventing costly repairs down the line. Wholesale chicken wire fencing is a cost-effective and versatile solution for securing and containing poultry and other animals on a farm or in a backyard. This type of fencing is made from galvanized steel wire that is woven into a hexagonal mesh pattern, creating a strong and durable barrier that can withstand the elements and potential damage from animals. The importance of masonry tie-backs is not just limited to their function as a physical support. They also contribute significantly to the overall aesthetics of the structure. By preventing bulging or cracking, they maintain the straightness and alignment of walls, preserving the visual appeal of the masonry work By preventing bulging or cracking, they maintain the straightness and alignment of walls, preserving the visual appeal of the masonry work

By preventing bulging or cracking, they maintain the straightness and alignment of walls, preserving the visual appeal of the masonry work By preventing bulging or cracking, they maintain the straightness and alignment of walls, preserving the visual appeal of the masonry work

By preventing bulging or cracking, they maintain the straightness and alignment of walls, preserving the visual appeal of the masonry work By preventing bulging or cracking, they maintain the straightness and alignment of walls, preserving the visual appeal of the masonry work masonry tie backs. The PDF then delves into the versatility of wire mesh, showcasing its extensive use in filtration, separation, and security applications. In construction, wire mesh is used as reinforcement in concrete, while in agriculture, it serves as fencing for livestock. The mining industry employs it for sieving and screening operations, and in architecture, it adds aesthetic appeal as a decorative element The mining industry employs it for sieving and screening operations, and in architecture, it adds aesthetic appeal as a decorative element

masonry tie backs. The PDF then delves into the versatility of wire mesh, showcasing its extensive use in filtration, separation, and security applications. In construction, wire mesh is used as reinforcement in concrete, while in agriculture, it serves as fencing for livestock. The mining industry employs it for sieving and screening operations, and in architecture, it adds aesthetic appeal as a decorative element The mining industry employs it for sieving and screening operations, and in architecture, it adds aesthetic appeal as a decorative element The mining industry employs it for sieving and screening operations, and in architecture, it adds aesthetic appeal as a decorative element The mining industry employs it for sieving and screening operations, and in architecture, it adds aesthetic appeal as a decorative element

The mining industry employs it for sieving and screening operations, and in architecture, it adds aesthetic appeal as a decorative element The mining industry employs it for sieving and screening operations, and in architecture, it adds aesthetic appeal as a decorative element wire mesh pdf. 2. Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them

wire mesh pdf. 2. Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them

Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them installing tomato cages. Make sure the cage is positioned securely in the ground to prevent it from tipping over once the plants start to grow. Another important accessory is the concrete formwork. Formwork provides the necessary shape and support for concrete during the pouring and setting process. It ensures that the concrete assumes the desired dimensions and shape, while also preventing it from leaking or spilling out It ensures that the concrete assumes the desired dimensions and shape, while also preventing it from leaking or spilling out

installing tomato cages. Make sure the cage is positioned securely in the ground to prevent it from tipping over once the plants start to grow. Another important accessory is the concrete formwork. Formwork provides the necessary shape and support for concrete during the pouring and setting process. It ensures that the concrete assumes the desired dimensions and shape, while also preventing it from leaking or spilling out It ensures that the concrete assumes the desired dimensions and shape, while also preventing it from leaking or spilling out It ensures that the concrete assumes the desired dimensions and shape, while also preventing it from leaking or spilling out It ensures that the concrete assumes the desired dimensions and shape, while also preventing it from leaking or spilling out

It ensures that the concrete assumes the desired dimensions and shape, while also preventing it from leaking or spilling out It ensures that the concrete assumes the desired dimensions and shape, while also preventing it from leaking or spilling out concrete construction accessories. High-quality formwork materials, such as plywood or steel, are essential for creating a smooth and even surface that requires minimal finishing.

concrete construction accessories. High-quality formwork materials, such as plywood or steel, are essential for creating a smooth and even surface that requires minimal finishing. 16 Gauge Dark Annealed Wire

Applications of Annealed Wire Conclusion Another significant advantage of bulk extension springs is their compact design Moreover, transportation costs should not be overlooked. The distance between the manufacturer and the consumer can add a substantial logistical expense, particularly for international shipments. Additionally, fluctuations in fuel prices can impact the final cost of the mesh. In the automotive industry, tension coil springs are used in vehicle suspension systems, providing a smooth ride by absorbing and damping road vibrations. They also find their way into seat mechanisms, ensuring comfortable seating and safety. In the aerospace sector, these springs are employed in landing gear systems, contributing to the aircraft's safe takeoff and landing.

Moreover, transportation costs should not be overlooked. The distance between the manufacturer and the consumer can add a substantial logistical expense, particularly for international shipments. Additionally, fluctuations in fuel prices can impact the final cost of the mesh. In the automotive industry, tension coil springs are used in vehicle suspension systems, providing a smooth ride by absorbing and damping road vibrations. They also find their way into seat mechanisms, ensuring comfortable seating and safety. In the aerospace sector, these springs are employed in landing gear systems, contributing to the aircraft's safe takeoff and landing.